A DRAINing Day

- Abigail Weeks

- Jun 16, 2018

- 2 min read

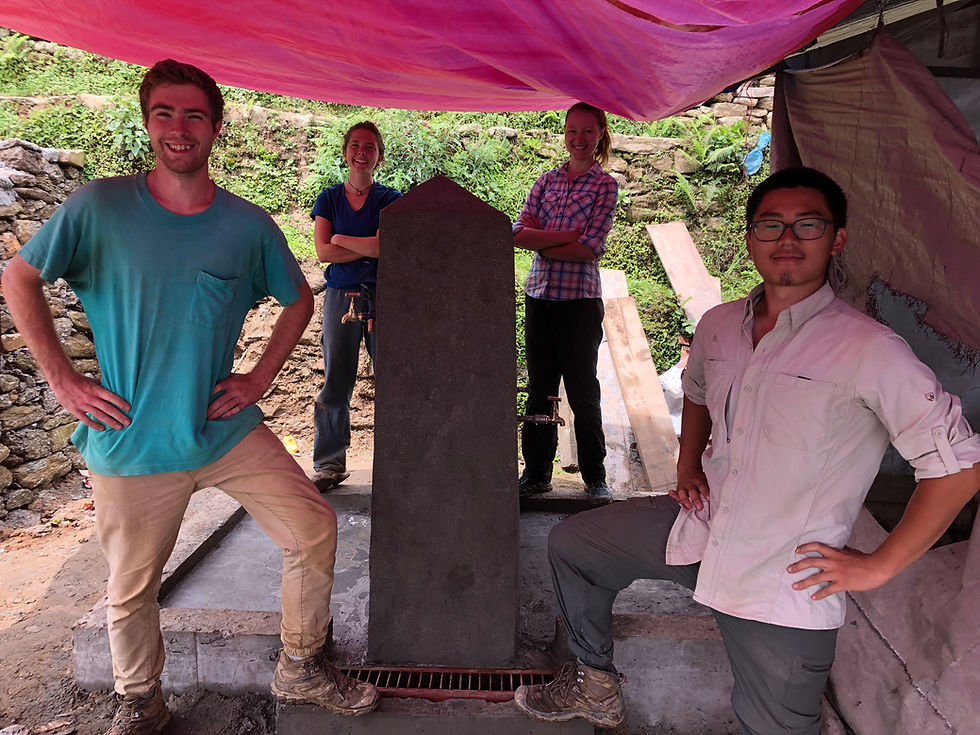

Saturdays are rest days in Nepal. Naturally, we hiked up to the school and resumed work on the drainage and overflow system for the tank. After a couple (like 6) redesigns and re-fittings we drained the tank and connected the pipes. It took a lot longer than expected due to a frustratingly oriented drain and less than desirable GI fittings, and after it was done we felt more relief than accomplishment.

Once we attached the new drainage system, we discovered, much to our dismay, that the 2 inch GI union at the end was too small to connect to the previously buried 63 mm HDPE drainage pipe. After brainstorming and conferring with Lisa we affixed a temporary solution by way of a 63mm HDPE socket loosely threaded onto a 2 inch GI nipple. It doesn’t seem to leak but in the future we want to change to a more secure brass union.

We also attached the newly buried 63mm drainage to the previously installed drainage that leads to the energy dissipation system.

All that’s left for work on the tank is to drill a hole and connect an existing 20mm line into it.

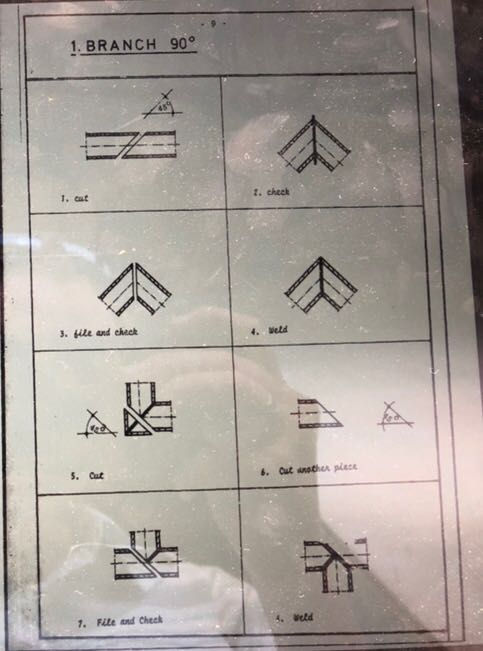

Down at the tap stands we are joining the drainage pipes. In order to do this we used a heating plate that melted pipe sections together to form a T. (See diagram)

We used a blow lamp (essentially a kettle that spits fiery kerosene) to heat up a metal plate. After briefly setting a desk on fire, we were able to hold two ends of pipe to the plate to melt the plastic and then “fuse” the joints together to form a right angle. Our first trial broke and we took tools down to the NCDC office this evening to make a new one.

We wrapped up the work for today waiting in the storeroom for the rain to pass. We all showered after an undisclosed amount of time and are now writing this blog.

TANKs for reading. Hope it was a heart-WRENCHing read. PIPE up in the comment section!

-Your favorite plumbers

What a FITTING end to your Saturday! Well done, team! Impressive all around!